Complete Industrial Wooden Packaging Services

Industrial wooden packaging services encompass a comprehensive range of services, materials, and technologies designed to meet the unique packaging needs of various industries.

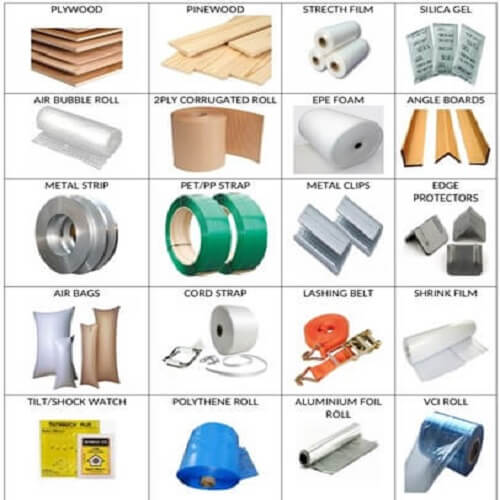

complete industrial wooden packaging services is to protect products from damage, contamination, and other risks throughout the supply chain. Packaging professionals consider factors such as shock and vibration resistance, temperature control, moisture protection, and product-specific handling requirements. They employ appropriate packaging materials, cushioning techniques, and protective measures to mitigate risks and safeguard product integrity. By ensuring proper product protection, complete industria lwooden packaging solutions minimize the likelihood of product loss, returns, and customer dissatisfaction, thereby strengthening brand reputation and customer loyalty.

Complete industrial wooden packaging solutions also address the growing need for sustainability and environmental responsibility. Packaging experts strive to minimize the environmental impact of packaging by promoting the use of eco-friendly materials, optimizing packaging designs for material efficiency, and implementing recycling and waste management programs.

VCI Packaging

Volatile Corrosion Inhibitor (VCI) is a type of corrosion inhibitor that is used to protect ferrous materials and non-ferrous metals against corrosion or oxidation where it is impractical to apply surface treatments. The cover comes in various thicknesses and depending on the type of cargo to be packed an appropriate thickness is used. VCI is available in different variants like VCI pouches, VCI Paper, VCI Stretch film etc.

VCI packaging services typically include the following components:

- VCI Packaging Materials: These materials are designed to release volatile corrosion inhibitors that create a protective layer on the metal surface, preventing moisture and oxygen from coming into contact with the metal. Common VCI packaging materials include VCI paper, VCI bags, VCI film, and VCI foam.

- Packaging Design: Engineers and packaging experts design the packaging to ensure that the VCI materials effectively protect the metal components or products. This may involve selecting the appropriate packaging type, size, and shape to fit the specific requirements.

- Packaging Process: VCI packaging services may include manual or automated packaging processes, depending on the scale and complexity of the project. The goal is to seal the metal items in VCI packaging materials to create a protective environment.

- Testing and Quality Assurance: Many VCI packaging services providers perform quality checks and tests to ensure that the VCI packaging effectively inhibits corrosion. This may involve accelerated corrosion testing or real-world exposure tests.

- Customization: VCI packaging services can be customized to meet the specific needs of different industries and applications. For example, automotive manufacturers may require VCI packaging for sensitive metal parts, while the aerospace industry may need VCI packaging for critical components.

- Supply Chain Integration: VCI packaging can be integrated into the supply chain to ensure that metal components remain protected during storage, transportation, and handling.

Vacuum packaging

Vacuum packing is a method of packaging that removes air from the package prior to sealing. This method involves placing the product to be packed in polythene cover, VCI cover, Aluminium foil, and removing air from inside and hot sealing the package. The intent of vacuum packing is usually to remove oxygen from the container to extend the shelf life of product.

Export/ Domestic Packaging

We offer wide range of packaging solutions that fulfill the requirements for export packing. The packaging is designed keeping in view the climatic conditions, voyage time , stacking pressures, vibrations, drops, climatic stresses, Humidity levels and the handling methods. Our main idea is to ensure that your product is free from damages and reaches safely at the point of destination. Export packaging is further categorized depends upon the mode of transportation like Air Worthy & Sea Worthy. The difference in domestic and export packaging is the process of packaging i.e., Type of wood and packaging materials used are different to provide cost effectiveness without affecting the functionality.